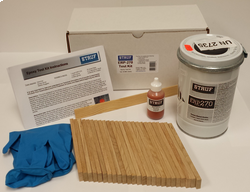

ERP-Kit for Concrete Testing

Test Kit Prior to Application of ERP-270

Special features

- Complete kit for concrete testing

Test Kit Prior to Application of ERP-270

Special features

| Product Description |

| This kit is designed to test job site conditions of concrete subfloors that would not require shot blasting. If the concrete fails this test, then shot blasting will be required before applying ERP-270. Evaluate the job site and calculate how many test areas are required. It is recommended one test be performed per 5,000 SF of flooring. At least one test must be performed on each floor of a multi-story building or each site of a multiple slab project. If concrete shows different colors or shade characteristics then it is recommended to perform at least one test for each area. All tests should be performed AFTER all necessary subfloor preparations such as wire brushing, sanding, grinding, vacuuming, etc. have been performed. All dust, paint, or other surface pollution must be removed by suitable means prior to the test. Do not treat test areas any differently than you would do the rest of the job site. |

| Pre-Installation Checklist |

| A successful installation requires proper preparation of the subfloor. Read and understand all applicable guidelines and technical data sheets before installation. Follow industry standards and flooring manufacturers' recommendations for subfloor moisture content, design, layout, and application of flooring materials. The backing of all flooring material must be solid, sound, and free of anti-adherents. All slab constructions must meet the specific requirements of the floor covering to be installed. |

| Sub Floor Examination |

| Do not apply the product to a visibly damp surface. Examine the concrete subfloor for color, cleanliness, porosity, and pre-existing residues PRIOR TO installation (see Technical Information #18 @ www.staufusa.com). Concrete subfloors must be checked for contaminants and/or anti-adherents using the STAUF Epoxy Test Kit (see Technical Information #16). |

| Prior to installation, the subfloor must be checked according to applicable installation guidelines. It must be solid, sound, clean, porous, free of chaps, anti-adherents, and resistant to pressure and tension. Confirm sufficient porosity by performing a water drop test according to ASTM F3191-16. Check for missing or compromised vapor barriers and hydrostatic pressure by carrying out RH or CaCl moisture tests following ASTM standards F1869-16 or F2170-19. Results of 99% RH or 25# CaCl could indicate a higher moisture content in the slab than what tests can measure, and there might be hydrostatic pressure and/or a compromised or missing vapor barrier. |

| Sub Floor Preparation |

| The subfloor's condition will determine which type of mechanical treatment is required (e.g., wire brushing, sanding, grinding, or shot blasting). Dust, paint, curing compounds, sealers, residual adhesives, or other surface contaminants MUST be removed, and a porous surface must be achieved by suitable means. The installer can only determine the extent of subfloor preparation at the site. Clean the surface with an industrial vacuum cleaner and tack the floor with a damp microfiber mop before application. Do not use sweeping compounds unless water-based, as most others contain oil or wax, which will act as an anti-adherent and prevent primers, sealers, leveling compounds, coatings, and/or adhesives from bonding to the concrete. Cracks and gaps must be treated before application of primers, sealers, leveling compounds, coatings, and/or adhesives (see Technical Information #19 @ www.staufusa.com). |

| Mixing of Components |

| Pierce through the lid and bottom of the upper part of the bucket using a screwdriver or similar tool. Let the hardener flow into the lower part of the bucket for about 1 minute. Remove the ring and the upper part of the pail and mix both components well using the stirrer provided until the color is uniform. Mix for at least three minutes. Make sure to mix along the wall and bottom of the container as well. The temperature of both components should be at least 50°F before mixing. Pour mixture on chosen test spots immediately to prevent the sealer from heating up and drying in the pail. Failure to use the entire contents of the pail within 20 minutes will result in the material hardening to a solid in the pail and will become very hot. |

| Installation Procedure |

| Absorption Test: Shake bottle before each use. Place a few drops of absorption liquid on the surface of the concrete and observe the time it takes for the liquid to be absorbed into the concrete. If the liquid is absorbed into the concrete in less than one minute the slab is absorbent and further testing is only necessary if the slab was poured more than one year ago. If the liquid is still unchanged after one minute the concrete is non-absorbent which could be caused by sealers, adhesives, curing compounds, or other contaminants. Proceed with the epoxy pull test. |

| Test Site Preparation: Pour thoroughly mixed content onto concrete into an 8? puddle on the sites to be tested (up to 5 sites per kit). Wait about 15 minutes to allow the sealer to spread to about 12? diameter, then set five pieces of the wood fillets into the puddle with half the wood into the edge of the puddle and half of the wood over dry concrete. Place the wood fillets in a wagon wheel pattern. Once the test site is completed, immediately move to the next test site and repeat as needed. Do not reseal the pail once mixed. |

| Perform Pull Test: Allow sealer to dry and cure for 72 hours. Using a hammer and screwdriver or pry bar, pry up the fillets on the outer edge over dry concrete until separation occurs. A good bond is when wood splits leaving part of the wood fillet in ERP-270 still adhered to concrete (B) or if the sealer separates from concrete but shows some concrete removed with the floor (A). Failed bond is when the sealer separates from concrete with no large concrete particles attached (C). This would indicate that more subfloor preparation is necessary. Take pictures of each test site after pulling up the fillets with the fillets being turned over and placed next to where the fillets were removed. |

| Limitations |

| Do not dilute primer/sealer or mix with other products. |

| Sealer will not prevent moisture damage from hydrostatic pressure, missing or compromised vapor barriers, underground springs, damaged water pipes, sinks, icemakers, faulty plumbing, flooding, etc. |

| In case of an accident, injury, spill, or exposure, see SDS for information. Consult the Technical Data Sheet at www.staufusa.com for updated information. |

| The foregoing representations are based on the results of our most current product and material testing within a controlled environment and are of a non-obligatory advisory nature only. As such, they do not constitute an express or implied warranty of any kind including the Warranty of Merchantability and/or Fitness for a Particular Purpose. Because we have no control over the actual quality of workmanship, materials used, and worksite conditions, STAUF USA LLC will in no event be liable for any incidental and/or consequential damages. Therefore, we strongly recommend that prior on-site testing be conducted to refer to and study the suitability of the product for the intended purpose. With the release of this Technical Information Sheet, all its prior versions become invalid. For warranty and warranty disclaimer information please see our Limited Lifetime Warranty @ www.staufusa.com |

|

|

||||||||||||||||||||||||||||||

| Revision: 2022-04-22 11:47:46 | |||||||||||||||||||||||||||||||